*...*...*. ..*...*...*...*...*. ..*...

BY RENAUD ANJORAN

As I mentioned in a previous article, more and more importers are switching their focus from standard QC inspections to improving key suppliers.

The question is, are inspections useless? What are their benefits, if any?

My opinion is, there are benefits but they depend on the kind of inspection. Here is Shingo‘s typology:

#1. “Judgement inspection” (prevents shipment of defective batches)

- Quantify, and if possible sort out, defects.

- Takes place after production is finished.

- Prevents defective lots from reaching the customer. But does not decrease the defect rate.

- Investigate sources of defects.

- Feed the information back to the processes.

- Implement corrective actions, in order to reduce the defect rate.

- Work on processes to prevent errors from happening, when possible.

- Work on processes to make sure errors are caught before they become defects.

What is realistic for importers?

For many importers sourcing from China, #1 is all the supplier will accept. And doing it during production, to catch problems early, is the best option when there is a high probability of problems.The sad truth is, most manufacturers are just not interested in implementing corrective actions and improving their processes.

In some cases, though, the factory accepts to follow recommendations coming out of #2. And they might even try to put in place #3 (if given proper guidance).

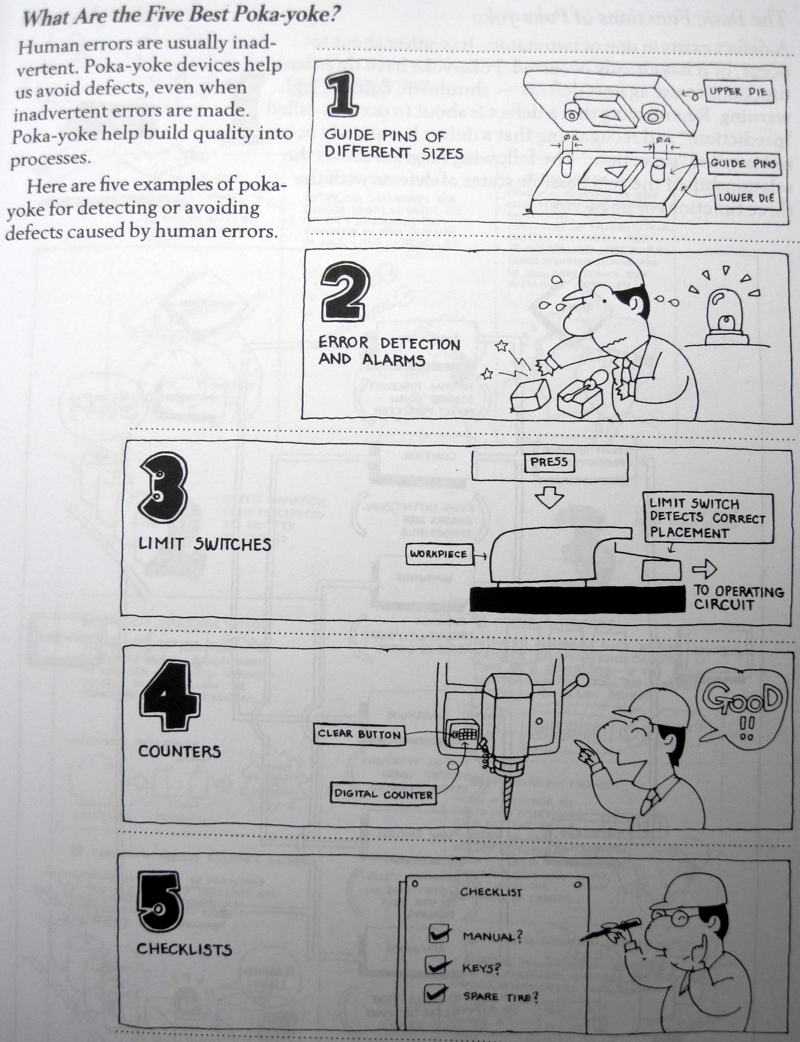

I understand that most purchasers are not familiar with #3 (source inspection). An essential element of source inspection is mistake-proofing devices and systems (“poka-yoke” in Japanese).

[See the appendix below this article if you are not familiar with poka-yoke.]

Why do many people think quality inspections are useless?

One of Deming‘s 14 points is as follows:Eliminate the dependence on inspection to achieve quality. Eliminate the need for inspection on a mass basis by building quality into the product in the first place.This point is often misunderstood. What he called “inspection” was judgement inspection only. And what he called “building quality into the product” included source inspection as well as smarter design & engineering.

Is statistical quality control the best way to reduce the number of defects?

Again, it depends. If you read Deming or a Six Sigma manual, statistics are the name of the game. If you read Shingo or a book about Lean, the most important is to find ways to avoid human mistakes.I like the way Michel Baudin puts these two approaches in perspective:

Our view is that the applicable tools for quality improvement depend on what the quality problems are. If they are primarily human error, then mistake-proofing will work. On the other hand, if they are due to insufficient process capabilities, then process characterization through statistical design of experiments will be much more help than mistake-proofing.In the vast majority of factories I have visited, human mistakes are the main cause of defects. Most Chinese managers focus on discipline instead of mistake-proofing. Instead of asking “why did it happen?”, they ask “who did it?”.

As long as this doesn’t change, their factories will keep churning out products of inferior quality.

What do you think?

—

APPENDIX: WHAT POKA YOKE IS

(The above carton comes from Poka-Yoke: Improving Product Quality by Preventing Defects).

http://www.sunchineinspection.com/benefits-of-quality-control-inspections/