Do you wonder why you still suffer from quality issues, even though the process is quite mature and seems to be well understood?

Or are you preparing to launch the production of a new product… or production of an existing product in a new factory? And you want to plan ahead to avoid missteps that might be quite costly?

There are 3 basic process improvement tools that you can use:

- The Process flow chart

- The Process FMEA (Failure Mode & Effects Analysis)

- The control plan (both for product and for process)

And there is a logical order that you can follow. Let’s go through these documents one by one.

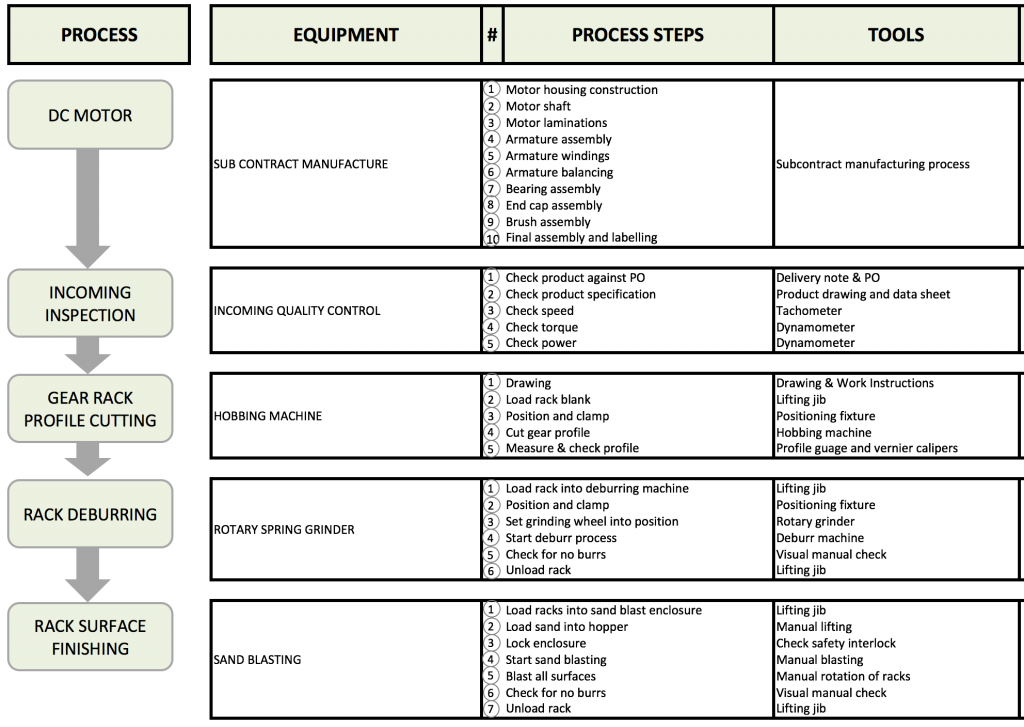

1. The Process Flow Chart

This is simply the mapping of the process steps. There are many templates you can follow, and here is an example.

Take a step back and look at this process. What steps can be combined (less picking & stacking, fewer mistakes, higher productivity)? Are there ways to eliminate one step (e.g. by clipping rather than positioning and then screwing)?

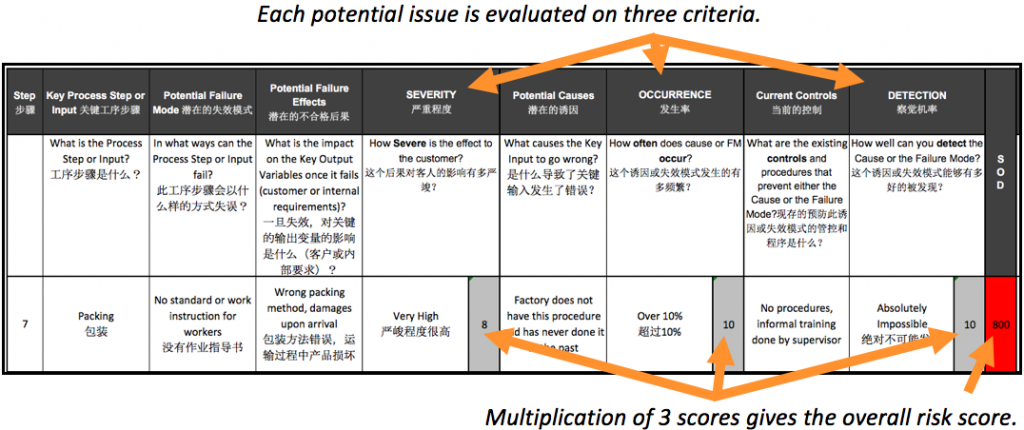

2. The Process FMEA

With the process map in hand, walk on the factory floor and observe each step. for each process, make a list of things that might go wrong (the “failure modes”). Bring in people from different teams and backgrounds if possible.

The FMEA is a great way to assess the risks and to rank them. The 3 components of risk in this form are:

- Severity of the impact (on the customer, on the downstream process…) if it happens

- Occurence — how often it is expected to happen

- Detection — how likely is it to be caught before it has an impact?

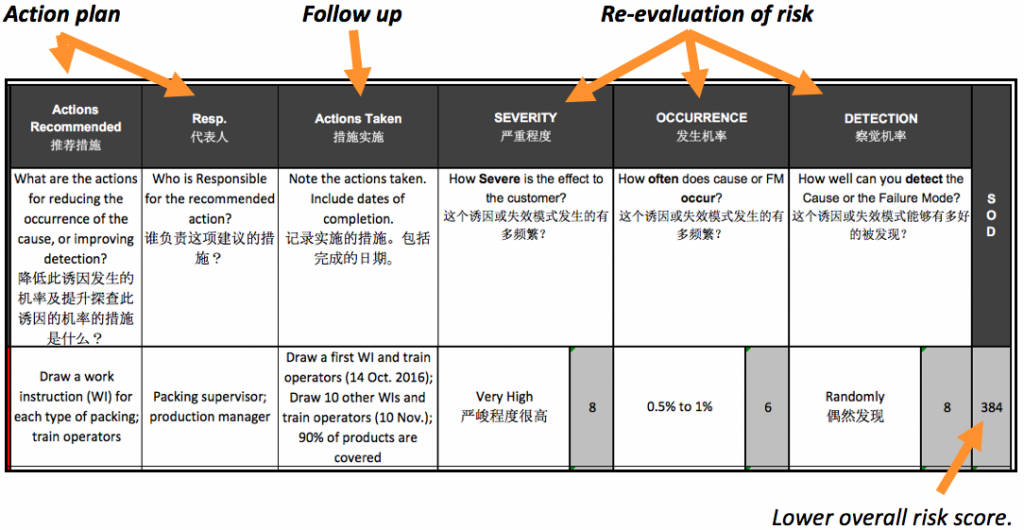

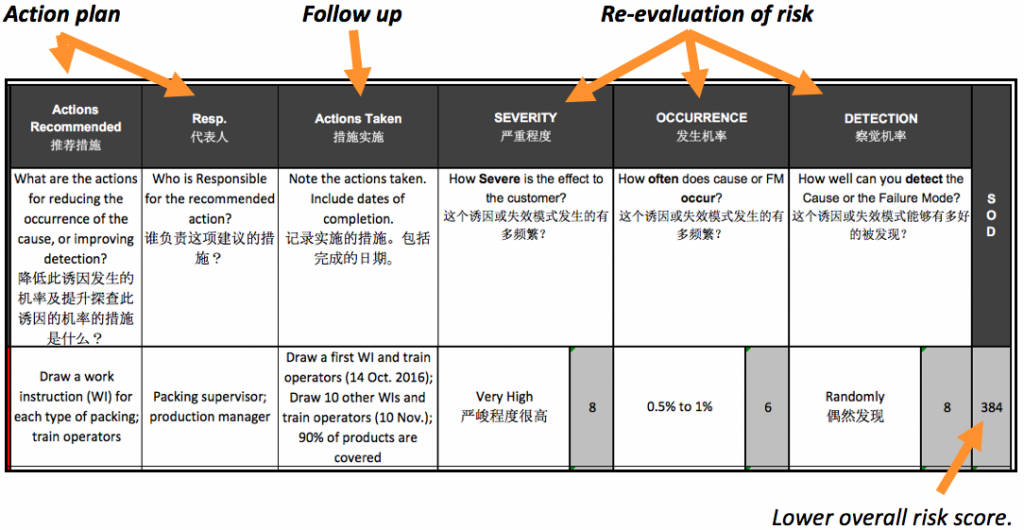

And then, for each failure mode, it drives an action plan. It is a living document and should be updated often.  (I covered the Process FMEA in more detail here.)

(I covered the Process FMEA in more detail here.)

(I covered the Process FMEA in more detail here.)

(I covered the Process FMEA in more detail here.)

A word of caution. It is not an easy exercise. Don’t expect a production supervisor or a quality auditor to do it nicely without prior training and experience.

In theory it is tool to think of issues that might come up in the future. But an easier way to start is to include the issues that issues that came up in the past… if that process has been in place for some time.

3. The control plan

Based on the above documents, you have:

- A map of the process steps

- A ranking of the highest risks to watch out for

This the basis for a good control plan — the central document that the factory should use to drive the process’ capability up (in other words, improve process controls so as to get better product quality).

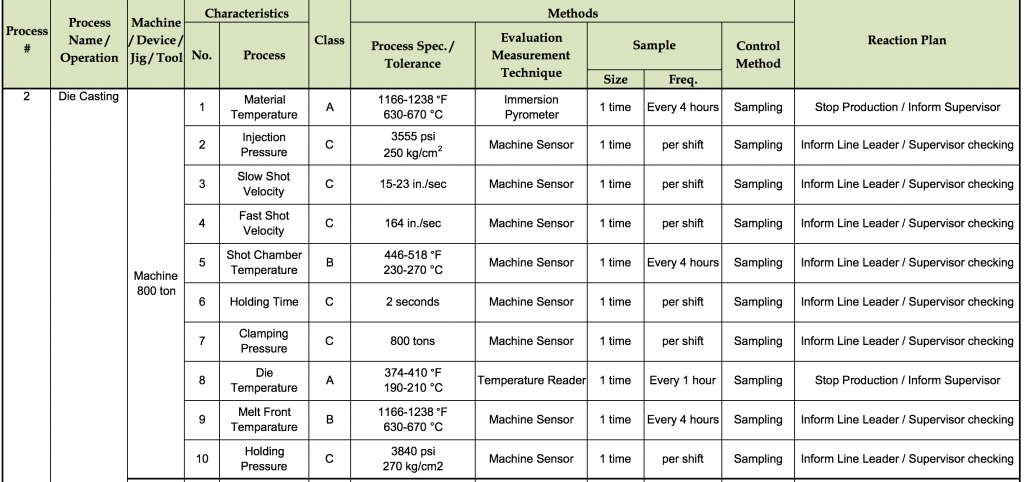

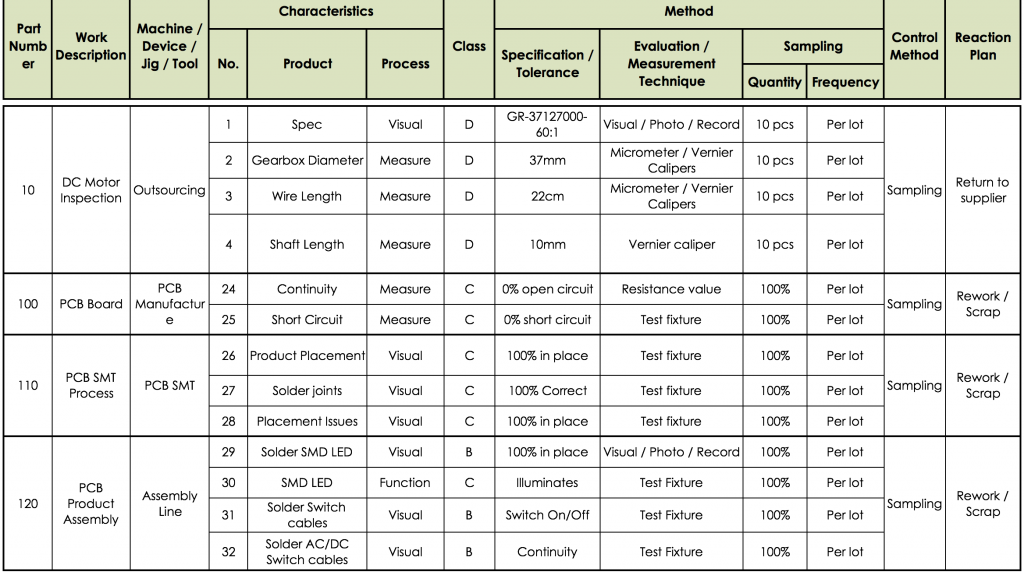

A good control plan includes:

- Process controls — in this example, what to check regularly on a die casting machine to ensure it works properly. (Note that the mould and the materials also need to be checked regularly — it’s not only about the machine.)

- Product controls — in this case, inspection of incoming components and inspection of some characteristics of semi-finished products. (It should also include inspection of completed products, obviously.)

Based on the control plan, proper work instructions can be given to the main interested parties:

- Production operators (who need to achieve that plan and do some of the checks when appropriate)

- Quality inspectors & engineers (who need to do some of the checks)

- Maintenance technicians (who need to know what the settings should be on the equipment)

- Purchasers (who need to buy the right components & materials)

- Customers (who need to know what specifications the manufacturer commits to, and who may want to audit the process controls)

—

I made this whole approach look very linear, but often those process improvement tools are developed at the same time. Each document feeds the other two.

Our consultants have developed these documents in a number of projects, with good results. They are quite powerful.

What do you think? Do you, or your suppliers, use these tools?

No comments:

Post a Comment